Key Challenges in Industrial Wastewater Treatment

1. Complex Composition of Industrial Wastewater

Industrial wastewater often presents a wide array of pollutants, making it difficult to treat effectively. These include:

- Mixed Pollutants: Oil, heavy metals, organic and inorganic compounds, making it difficult to apply a single treatment method.

- Unpredictable Contaminant Levels: Variations in pollutant types and concentrations complicate the treatment process, leading to higher operational uncertainty.

- Secondary Pollution Risks: Treating complex wastewater can generate secondary pollutants that affect the environment and operational stability.

- High Treatment Costs: Due to the complexity of the wastewater composition, a multi-stage treatment process is often required, which increases both investment and maintenance costs.

These challenges result in increased operational expenses and environmental risks, making effective treatment of complex industrial wastewater a critical issue.

2. High Salinity in Industrial Wastewater

High salinity in industrial wastewater presents several specific challenges:

- Corrosion of Equipment: High salt concentrations accelerate the corrosion of machinery and piping, leading to increased maintenance and replacement costs.

- Scaling: Salt can form scale on equipment surfaces, reducing heat exchange efficiency and requiring frequent cleaning and maintenance.

- Energy-Intensive Treatment: Treating high-salinity wastewater typically demands higher energy consumption, making the process more costly.

- Impact on Downstream Processes: High salinity can cause membrane fouling during concentration stages, lowering treatment efficiency and increasing the frequency of membrane replacements.

The presence of high salt makes treatment not only more expensive but also more technically demanding, impacting overall wastewater management processes.

3. High COD in Industrial Wastewater

High Chemical Oxygen Demand (COD) wastewater is another significant challenge:

- High Pollution Load: Wastewater with high COD levels contains a large amount of organic matter, which is difficult to remove with traditional treatment methods.

- Increased Oxidation Demand: High COD wastewater requires a substantial amount of oxidizing agents, leading to increased production of secondary pollutants such as tail gases.

- Longer Treatment Times: Biodegradation or chemical oxidation processes for high COD wastewater are time-consuming, resulting in longer treatment cycles.

- Higher Energy Consumption: The extended treatment times and increased oxygen demand lead to higher energy costs, further raising operational expenses.

Treating high COD wastewater adds significant complexity and costs to industrial wastewater management.

Wastewater Sources:

As environmental regulations become increasingly stringent, industries are facing growing challenges in treating industrial wastewater and landfill leachate. These wastewater streams often contain high COD, high TDS, oil, and other complex pollutants. We provide comprehensive solutions to address these challenges, reduce operational costs, and ensure environmental compliance, while achieving Zero Liquid Discharge (ZLD) for industrial wastewater.

WSD’s Solutions

Advanced Industrial Wastewater Treatment Technologies

Our industrial wastewater treatment solutions are designed to address the most challenging wastewater streams, achieving Zero Liquid Discharge (ZLD) through a multi-stage process.

1. Efficient Pretreatment

We use advanced physical and chemical methods for pretreatment, which include:

- Screen to remove large debris,

- DAF (Dissolved Air Flotation)and ceramic membranes to eliminate suspended solids,

- Emulsion Breakingfor emulsified oils, followed by bag filters to remove remaining solids and pollutants.

This pretreatment step ensures that the water is prepared for more advanced treatment stages, enhancing the overall efficiency.

2. Membrane Concentration Technology

We utilize state-of-the-art membrane technologies such as HERO, STRO, ED, and DTRO to effectively reduce TDS levels and improve the concentration efficiency of industrial wastewater. These technologies use specialized membranes to filter out dissolved salts and other contaminants, optimizing the treatment process.

3. Evaporation Crystallization

Our evaporation crystallization process transforms concentrated salts into solid crystals, enabling the achievement of Zero Liquid Discharge (ZLD). This method significantly reduces the volume of wastewater, transforming it into solid waste that is easier and more environmentally friendly to dispose of.

4. Innovative Drying Technology

For the residual brine left after evaporation crystallization, we employ innovative drying technologies that remove excess moisture, further reducing energy consumption and improving the efficiency of the treatment process.

Industry Benefits

1. It operates without generating harmful gas emissions or thermal pollution.

2. The system features fully automated control for seamless operation.

3. Its design is standardized, modular, and skid-mounted for easy installation and maintenance.

4. The evaporator includes automatic discharge and cleaning functions to enhance efficiency.

5. It is equipped with cloud platform management for remote monitoring and control.

6. The system supports companies in achieving zero discharge of electroplating wastewater.

Customer Pain Point Analysis

We understand that each customer faces unique challenges in industrial wastewater treatment. Here are some examples of how we address these issues:

Customer A:

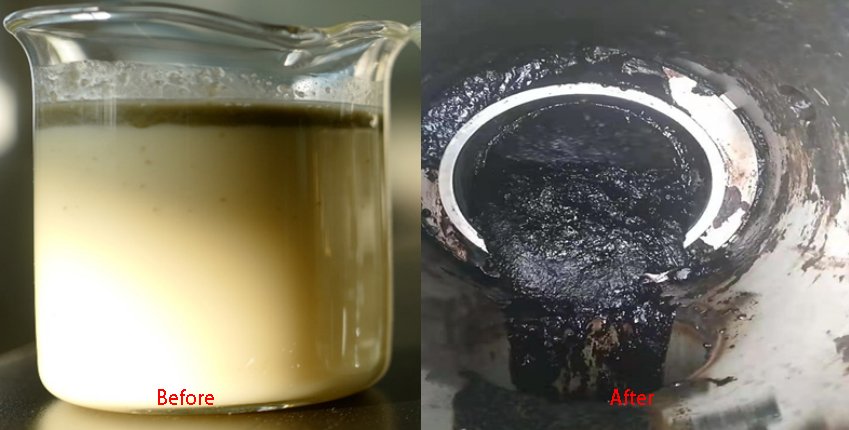

- Original Treatment Method: Oil separation, filtration, pH adjustment with chemicals, press filtration, and biological treatment.

- Wastewater Composition: Emulsified oils, cutting fluids, and other complex components with high COD.

- Pain Point: The complex composition leads to instability in the biological treatment system, causing frequent failures that disrupt production.

Customer B:

- Original Treatment Method: Outsourced treatment.

- Wastewater Composition: Sodium sulfate and sodium chloride mixture.

- Pain Point: High salt concentration necessitates regular discharge, while spray nozzles in cooling towers often clog, affecting cooling efficiency and rendering steam unavailable.

Customer C:

- Original Treatment Method: Membrane concentration followed by triple-effect evaporation.

- Wastewater Composition: Emulsified oils, cutting fluids, etc.

- Pain Point: Issues with clogging and cleaning in the triple-effect evaporation system lead to inefficiency. Due to high COD, traditional methods struggle, prompting the customer to choose our skid-mounted high-concentration waste liquid treatment system.

Customer D:

- Original Treatment Method: Chemical coagulation and dosing.

- Wastewater Composition: High levels of heavy metals, salts, and ammonia.

- Pain Point: Traditional methods such as dosing, sedimentation, and filtration are inadequate for treating high-salt wastewater, limiting processing capacity and effectiveness.

Why Choose Us?

With years of experience and cutting-edge technology, we provide highly efficient and cost-effective solutions for industrial wastewater treatment. Our solutions help businesses meet increasingly stringent environmental regulations and improve operational efficiency.

Industrial Wastewater Zero Discharge Solutions: As a leader in industrial wastewater treatment, we specialize in zero liquid discharge (ZLD) solutions, offering a combination of multiple processes to provide the most effective treatment tailored to each customer’s needs.

Pilot Testing Services: We offer comprehensive pilot testing services to demonstrate the effectiveness of our solutions. This service is available upon request, ensuring that customers receive precise and reliable data before full-scale implementation.

Water Quality Testing Services: We provide detailed water quality testing services, which allow us to accurately assess the wastewater characteristics and determine the best treatment strategy. These services are available upon application to ensure tailored solutions.

Commitment to Optimal Solutions: Unlike single-product manufacturers who may prioritize pushing their own product over the best solution for your needs, we focus on delivering the most effective and comprehensive treatment strategy, no matter which combination of technologies best addresses the problem.

Contact Us

Ready to achieve Zero Liquid Discharge for your industrial wastewater? Contact us today for a customized consultation. Our experts will provide you with comprehensive solutions to meet your wastewater management needs.