Background

Petrochemical wastewater primarily originates from petrochemical plants, where it generates various pollutants such as oil, sulfur, alkali, and salt after undergoing a series of processes. Some components of its main pollutants, such as hydrogen sulfide, ammonia compounds, and trace heavy metals, are either difficult or unable to be biodegraded, thus posing challenges in wastewater treatment and leading to resource wastage.

The main characteristics of petroleum chemical wastewater are as follows:

- Large capacity, complex and variable water quality: Petrochemical production tends to be large-scale, involving the addition of various solvents, additives, and agents, followed by various reactions. Consequently, wastewater has a large volume and considerably complex composition.

- Severe organic pollution: Organic substances in petrochemical wastewater are mainly hydrocarbons and their derivatives. Even after high-concentration waste liquid from certain petrochemical units undergoes incineration or other appropriate treatments, the COD remains high.

- Presence of heavy metals in wastewater: Many reactions in petrochemical production are catalyzed, and a large petrochemical plant may use dozens of catalysts. As a result, wastewater often contains heavy metals.

Pain points

Currently, the treatment of concentrated brine in the petrochemical industry mainly relies on two technologies: “membrane concentration + evaporation crystallization to prepare mixed salts” and “membrane separation + evaporation crystallization and fractionation.” However, in the final evaporation crystallization stage, due to the structural characteristics of traditional tubular evaporators, there is always a stream of mixed salt mother liquor, which has been a persistent issue in the full-process zero discharge treatment process for petrochemical wastewater. This mixed salt mother liquor exhibits the following characteristics:

- Large production volume, typically 5-10% of the front-end evaporation system.

- “Four highs and one low,” namely “high COD, high color, high toxicity, high salinity, low B/C ratio,” making it difficult to biodegrade and degrade.

- High moisture content, making it difficult for traditional evaporators to further concentrate and crystallize, and difficult to be used as waste salt for resource heat treatment.

- Long-term recycling within the system leads to reduced efficiency of the evaporator, frequent cleaning, and even paralysis.

- Long-term circulation without discharge leads to changes in the water quality of the evaporation and crystallization device, affecting the quality of the front-end by-products such as color, TOC, etc.

- High cost and high risk when outsourced as hazardous waste.

- High environmental risk, easily disrupting the ecological balance.

Current traditional mother liquor disposal devices, such as single-effect/single-vessel/rake drying/drum drying, are used in the industry. However, based on actual application results, they fail to address the need for drying this mixed salt mother liquor and bring new operational challenges to customers, such as:

- Unable to achieve drying.

- High equipment failure rate, prone to paralysis.

- Frequent cleaning, poor on-site hygiene environment.

- Overall disposal efficiency is low, with high energy consumption and low automation level.

WSD’s Solution

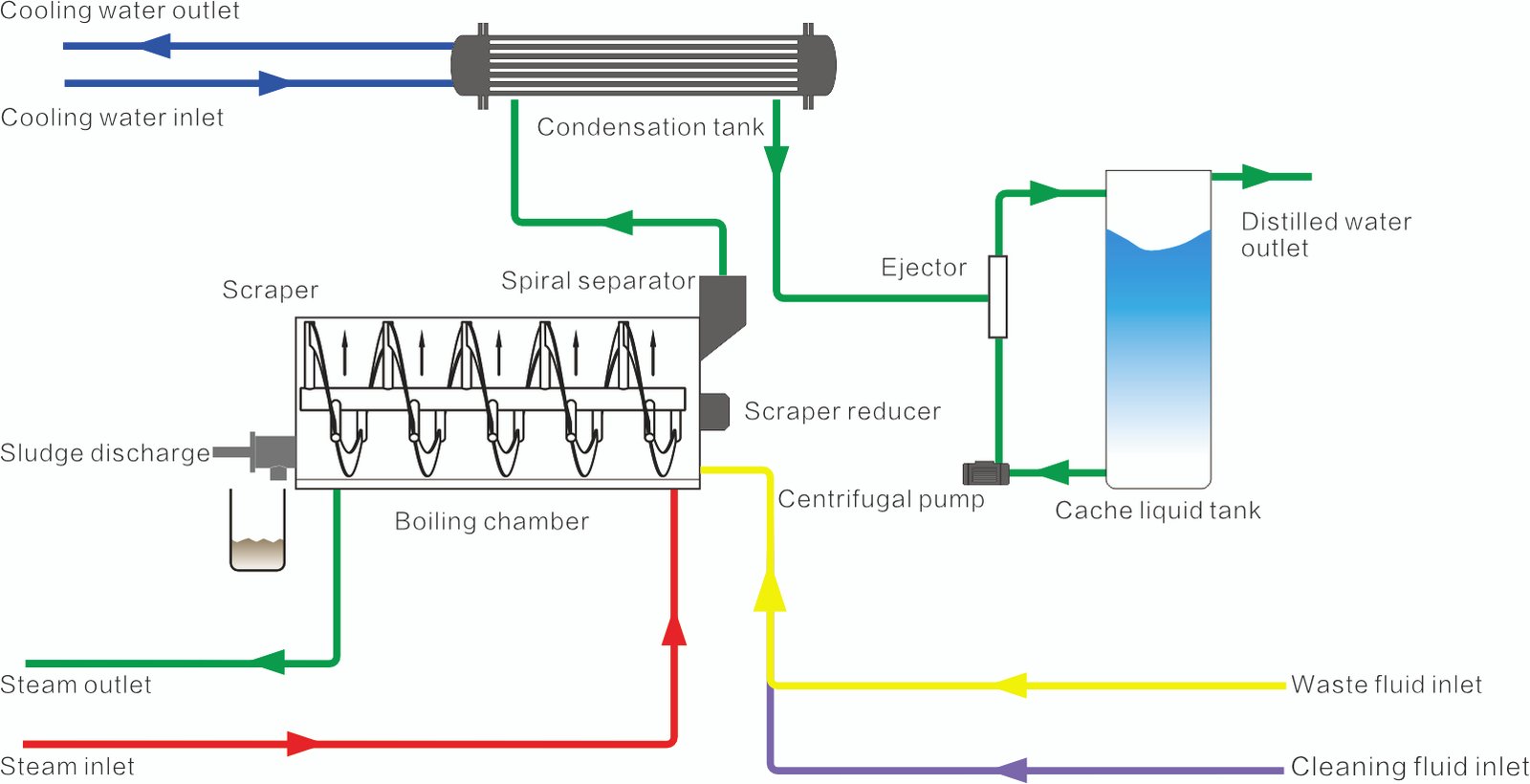

To address the challenge of drying mixed salt mother liquor in coal chemical end-of-pipe treatment, WSD Environmental Protection has dedicated years of research and innovation to develop a process that maximizes the drying of mixed salt mother liquor. The process adopts Miller plate heat exchange technology, with a vacuum degree in the evaporation chamber maintained at -95 to -97 kPa, and the evaporation temperature generally kept between 40 to 45°C. Inside the evaporation chamber, a spiral scraper agitation is employed to ensure uniform heating. Additionally, heating around the periphery of the agitation enhances heat transfer efficiency, improving the dryness of the discharged material.

Advantages

1. It operates without generating harmful gas emissions or thermal pollution.

2. The system features fully automated control for seamless operation.

3. Its design is standardized, modular, and skid-mounted for easy installation and maintenance.

4. The evaporator includes automatic discharge and cleaning functions to enhance efficiency.

5. It is equipped with cloud platform management for remote monitoring and control.

6. The system supports companies in achieving zero discharge.