Background

The lithium battery industry in the new energy sector generates wastewater mainly during the cleaning of the positive and negative electrode mixing tanks. The characteristics of this wastewater include a small volume, complex composition, poor biodegradability, and certain toxicity. The main components include lithium nickel cobalt manganese oxide, NMP (N-methyl-2-pyrrolidone), PVDF binder, SP, SBR binder, graphite, and small molecular organic esters.

Pain points

Currently, in the new energy sector, the battery industry generates wastewater from the production of iron phosphate and ternary precursor materials. After undergoing pretreatment, particularly through the MVR (Mechanical Vapor Recompression) system, a high-concentration evaporated mother liquor is produced. The enrichment of this high-concentration evaporated mother liquor will reduce the evaporation efficiency of the MVR system, necessitating periodic discharge. The treatment of the discharged high-concentration evaporated mother liquor poses a significant challenge for the industry.

WSD’s Solution

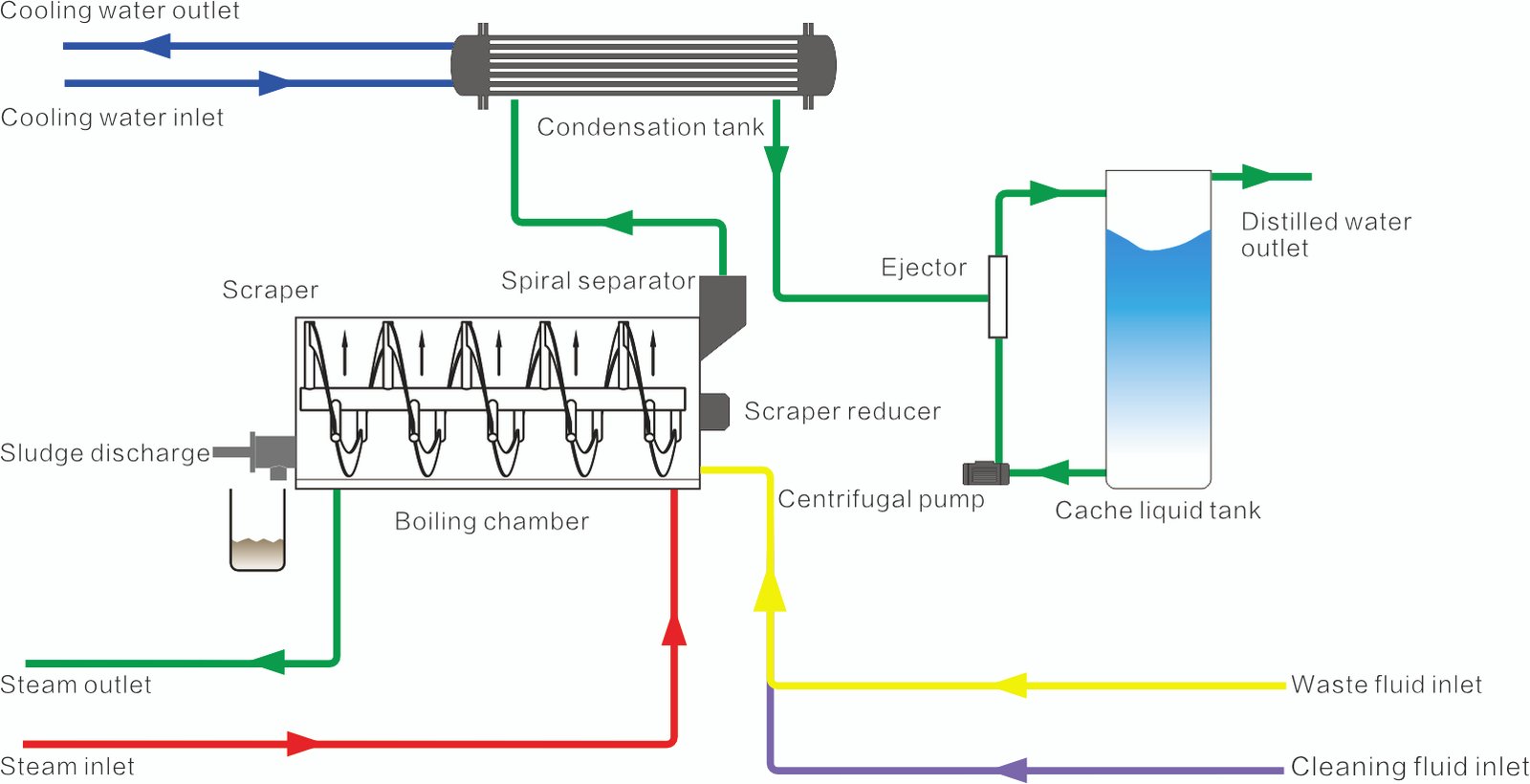

To address the disposal challenges of concentrated mother liquor in the fine chemical industry, WSD has devoted years of research and innovation to develop a process that minimizes the volume of concentrated mother liquor. The process adopts Miller plate heat exchange technology, with a vacuum degree in the evaporation chamber maintained at -95 to -97 kPa, and the evaporation temperature generally kept between 40 to 45°C. Inside the evaporation chamber, a spiral scraper agitation is employed to ensure uniform heating. Additionally, the heating effect is enhanced by setting up agitation around the periphery, thereby improving the dryness of the discharged material.

Advantages

1. It operates without generating harmful gas emissions or thermal pollution.

2. The system features fully automated control for seamless operation.

3. Its design is standardized, modular, and skid-mounted for easy installation and maintenance.

4. The evaporator includes automatic discharge and cleaning functions to enhance efficiency.

5. It is equipped with cloud platform management for remote monitoring and control.

6. The system supports companies in achieving zero discharge.