Introduction

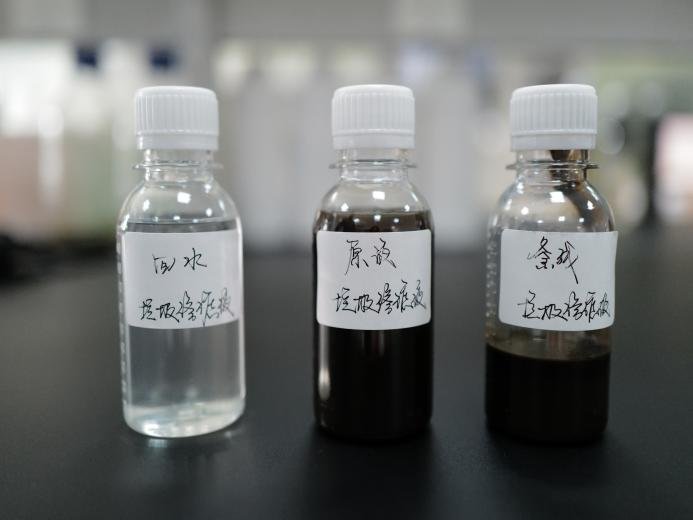

Hazardous waste water comes from a wide range of sources and is complex in nature. Its main sources include the chemical industry, petroleum refining industry, metal industry, mining industry, pharmaceutical industry, and others. It mainly consists of acidic wastewater, production process wastewater, cleaning wastewater, high-temperature cooking wastewater, and so on.

Hazardous

Hazardous waste water originates from various hazardous processing procedures, containing multiple alkaline substances and high concentrations of salts internally. Its biochemical properties are poor. Without treatment, it can cause irreversible effects on the water used in production process systems. Additionally, it can corrode mechanical equipment, disrupt normal industrial production, and lead to certain safety incidents.

Wastewater Sources:

Process

To address the challenge of disposing hazardous waste landfill leachate, WSD Environmental Protection has developed low-temperature heat pump evaporators and low-temperature evaporative crystallizers, which can achieve wastewater concentration and reduction.

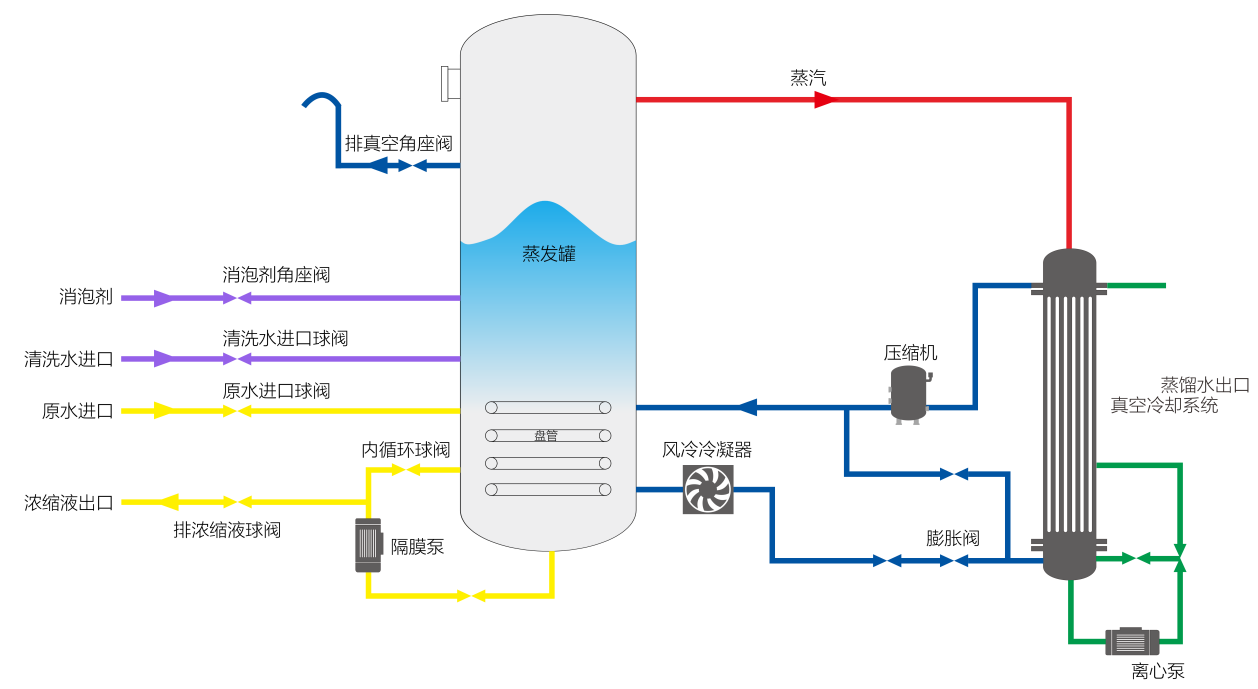

The process principle of the low-temperature heat pump evaporator is as follows:

- Preheating: This step is fully automatic. Once the water level in the original barrel reaches the middle level, the water pump starts to create a vacuum. The evaporator automatically fills with water, and the compressor generates heat to heat the wastewater in the evaporator tank. Under vacuum conditions, the temperature of the wastewater rises to around 30°C, and evaporation begins. Preheating is completed.To address the challenge of disposing hazardous waste landfill leachate, WSD Environmental Protection has developed low-temperature heat pump evaporators and low-temperature evaporative crystallizers, which can achieve wastewater concentration and reduction.

- The process principle of the low-temperature heat pump evaporator is as follows:

- Evaporation and concentration process: The evaporation temperature is set at 35-40°C. The compressor compresses the refrigerant to generate heat, causing rapid evaporation of water. Meanwhile, the refrigerant absorbs heat by gasifying through the expansion valve for cooling. The vapor rises and liquefies upon encountering cold liquid, entering the water storage tank. The refrigerant absorbs heat and, through compressor compression, provides additional heat to the wastewater. If bubbles rise during the evaporation process, the sensor detects them, and defoaming agent is automatically added to eliminate them. After completing one cycle, concentrated liquid begins to be discharged (the duration of one cycle can be set).

- Discharge of concentrated liquid: After completing one evaporation cycle, the compression pump stops working, and the pneumatic valve of the concentrated liquid pipeline opens. The evaporator tank is pressurized, and the concentrated liquid is pumped into the concentration tank.

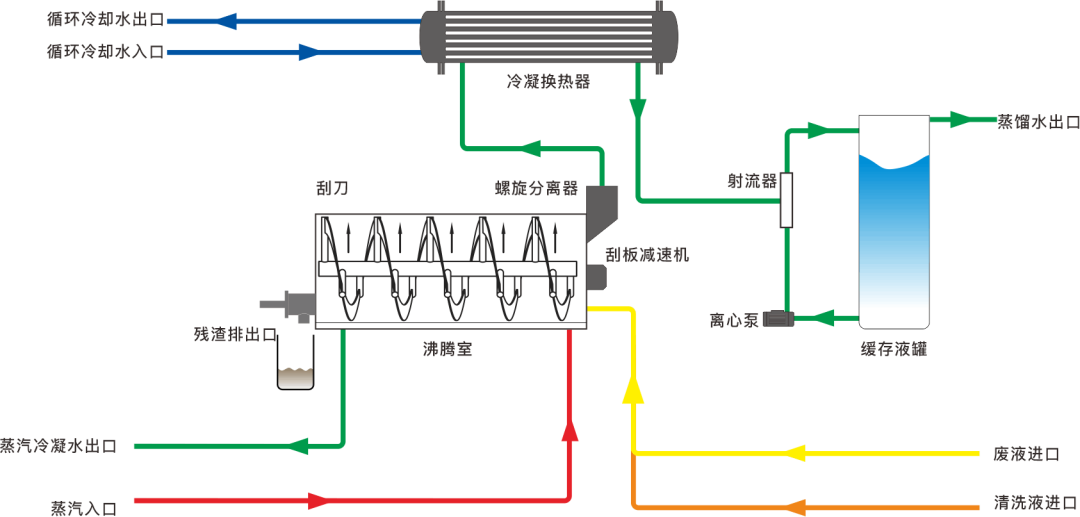

Low-temperature evaporation and crystallization process principle: After electroplating wastewater is injected into the low-temperature evaporation crystallizer, steam is automatically introduced, and the distillation tank is heated using steam as a heat source within the jacket. Under vacuum conditions, the boiling point of water is lowered, causing continuous concentration within the evaporation kettle. The water vapor is filtered and enters the condenser for recovery and output. Internal scrapers automatically rotate in both directions to prevent scale or coking formation. Residues are automatically discharged and disposed of externally.

Advantages

1. It operates without generating harmful gas emissions or thermal pollution.

2. The system features fully automated control for seamless operation.

3. Its design is standardized, modular, and skid-mounted for easy installation and maintenance.

4. The evaporator includes automatic discharge and cleaning functions to enhance efficiency.

5. It is equipped with cloud platform management for remote monitoring and control.

6. The system supports companies in achieving zero discharge of hazardous wastewater.