Introduction

“High-salinity wastewater” refers to wastewater with a mass fraction of total salts of at least 3.5%, containing soluble inorganic salt ions such as Cl-, SO2-, Na+, Ca2+, etc. Although these ions are essential nutrients for microbial growth and play important roles in the microbial growth process.

“High-COD wastewater” refers to wastewater that consumes a relatively high amount of oxygen under certain conditions when treated with strong oxidants. COD is an indicator of the amount of reducible substances in water. A higher COD value indicates a higher degree of pollution in the water.

Hazardous

Excessive concentration of soluble inorganic salt ions in high-salinity wastewater can inhibit and poison microorganisms, severely affecting the purification efficiency of biological treatment systems.

High COD wastewater can cause significant harm: On one hand, the reducing substances in the water can disrupt the balance of the aquatic environment, resulting in the death of almost all organisms except microorganisms, further impacting the surrounding environment. On the other hand, the complex composition of organic pollutants in the water, with some organic compounds being highly toxic (such as benzene and phenol), poses significant hazards to both the aquatic environment and human health.

Wastewater Sources:

Process

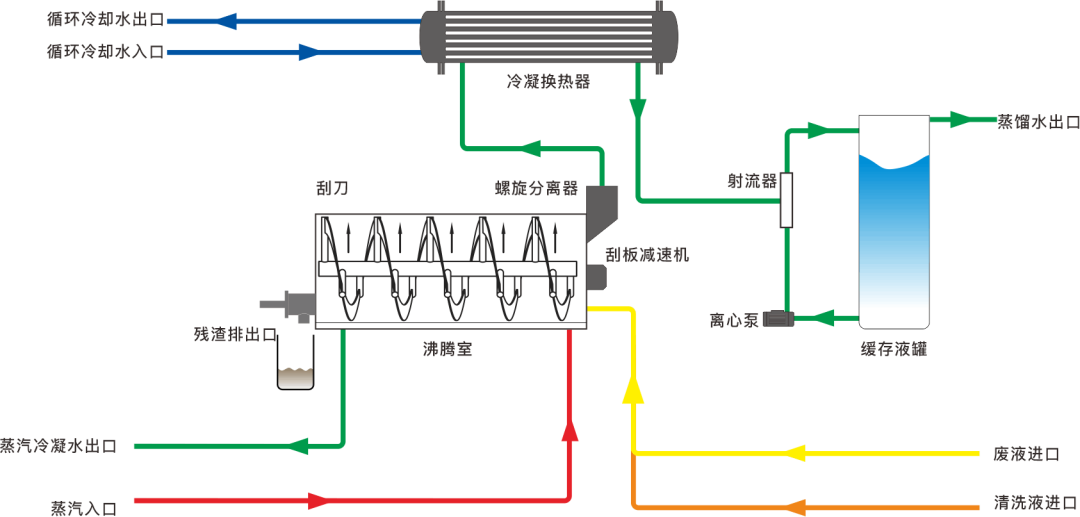

To address the challenge of treating wastewater from phosphoric acid iron and trivalent precursor materials, WSD Environmental Protection has developed a low-temperature evaporative crystallizer, which reduces energy consumption by over 50% and lowers operating costs. When wastewater from phosphoric acid iron and trivalent precursor materials undergoes pre-filtration and enters the low-temperature vacuum evaporative crystallizer, it evaporates under vacuum and low-temperature conditions. The water vapor condenses into distilled water during the vacuum extraction process, which is collected in a clean water tank. The remaining residue in the distillation kettle is collected in drums for further processing. This process significantly reduces or even eliminates harmful chemicals and heavy metals in the wastewater. The evaporation rate of the equipment can reach over 60%. Through pre- and post-treatment processes, the effluent is clear and transparent, meeting biochemical water quality standards, allowing for water reuse or discharge to meet standards. Residues are automatically discharged and transported for disposal.

Latest Technology

Advantages

1. It operates without generating harmful gas emissions or thermal pollution.

2. The system features fully automated control for seamless operation.

3. Its design is standardized, modular, and skid-mounted for easy installation and maintenance.

4. The evaporator includes automatic discharge and cleaning functions to enhance efficiency.

5. It is equipped with cloud platform management for remote monitoring and control.

6. The system supports companies in achieving zero discharge of electroplating wastewater.