Introduction

Currently, in the new energy sector, the production of phosphoric acid iron and trivalent precursor material wastewater in the battery industry, after undergoing preliminary treatment, especially the MVR system, will generate a high-concentration evaporator mother liquor. The enrichment of the high-concentration evaporator mother liquor will reduce the evaporation efficiency of the MVR system and must be discharged regularly. The treatment of discharged high-concentration evaporator mother liquor is a challenging issue in the industry.

Hazardous

The pollutants in the wastewater from phosphoric acid iron and trivalent precursor materials are complex, prone to scaling, and difficult to treat. They may pose the following hazards:

Heavy Metal Pollution: Chemicals containing heavy metals such as nickel, cobalt, etc., may be used or generated during the production process of phosphoric acid iron and trivalent precursor materials. If these heavy metals enter the wastewater, they may cause water pollution and pose risks to ecosystems and human health.

Chemical Residue: Chemicals used in the production process, such as solvents, acids, alkalis, etc., may remain in the wastewater. These chemicals may contaminate the water and even be toxic to aquatic organisms.

pH Influence: Some production processes may change the acidity or alkalinity of the wastewater, affecting the pH of the water. Wastewater that is too acidic or too alkaline may disrupt the habitat of aquatic organisms and even affect soil fertility.

Biotoxicity: Substances such as organic matter and heavy metals in the wastewater may have toxic effects on aquatic organisms, disrupting the balance of aquatic ecosystems.

Water Resource Waste: If untreated wastewater is discharged, it will lead to the waste of water resources. Moreover, untreated wastewater may also pollute surrounding soil and groundwater, affecting crop growth and human health.

Wastewater Sources:

Process

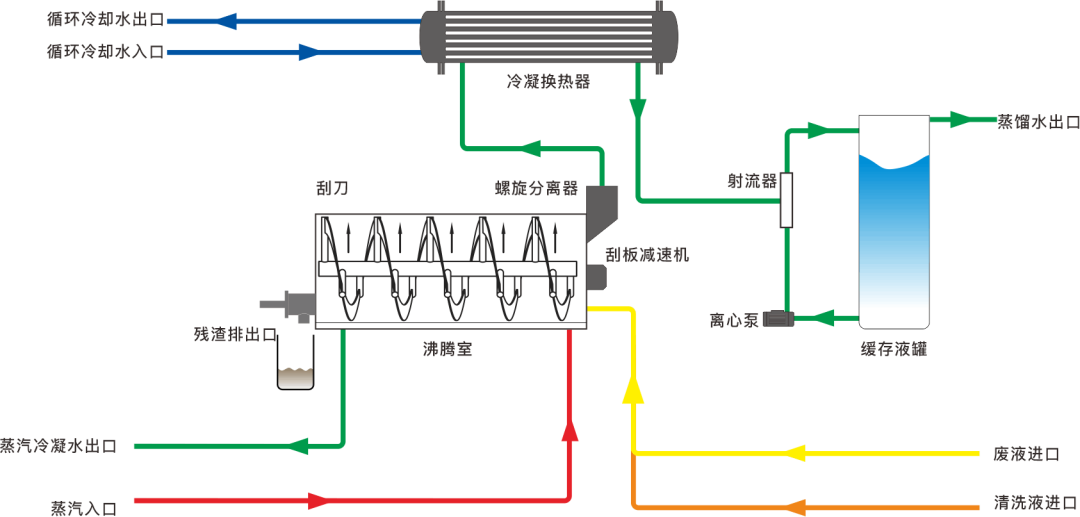

To address the challenge of treating wastewater from phosphoric acid iron and trivalent precursor materials, WSD Environmental Protection has developed a low-temperature evaporative crystallizer, which reduces energy consumption by over 50% and lowers operating costs. When wastewater from phosphoric acid iron and trivalent precursor materials undergoes pre-filtration and enters the low-temperature vacuum evaporative crystallizer, it evaporates under vacuum and low-temperature conditions. The water vapor condenses into distilled water during the vacuum extraction process, which is collected in a clean water tank. The remaining residue in the distillation kettle is collected in drums for further processing. This process significantly reduces or even eliminates harmful chemicals and heavy metals in the wastewater. The evaporation rate of the equipment can reach over 60%. Through pre- and post-treatment processes, the effluent is clear and transparent, meeting biochemical water quality standards, allowing for water reuse or discharge to meet standards. Residues are automatically discharged and transported for disposal.

Latest Technology

Advantages

1. It operates without generating harmful gas emissions or thermal pollution.

2. The system features fully automated control for seamless operation.

3. Its design is standardized, modular, and skid-mounted for easy installation and maintenance.

4. The evaporator includes automatic discharge and cleaning functions to enhance efficiency.

5. It is equipped with cloud platform management for remote monitoring and control.

6. The system supports companies in achieving zero discharge of precursor materials wastewater.